ALE Spec에 보면 Condensate trap for wet gas라는 부분이 있습니다. Wet gas일 경우 condensate가 무조건 설치 되어야 하고 응축수를 배출해야 한다. Separator와 condensate trap system을 요구합니다.

Condensate trap system

Condensates are collected at low point and drained through a condensate trap system (e.g. Drain-all). The condensate outlet shall be at leat 50mm (2-inch) diameter, but preferable 100mm (4-inch).

Efficiency of condensate draining systems for machine coolers shall be specified by the machine designer.

Condensate trap system for after cooler (with "Drain-All" or Bekomat Equipment)

For the last subcooler upstream of the Front End Purification (F.E.P) (and to make sure that liquid water cannot enter in F.E.P), it is prefereble to install two condensate traps, the second one as a backup. When the first one fails, the water level increases and an alarm is sent (LSH). Even if the second trap is out of order, the level further increases and a second alarm is sent (LSHH). This second alarm shuts down the unit. Figure 12 shows the differences between the two systems with Drain-All and Bekomat type traps.

The sample point of the bypass manual valve shall be located below the connection point of the LSH so that in case this manual valve is opened the condensates level can be drained below the alarm level.

Water Drainage

If the water flows in the shell, a draining decantation pot (diameter 100mm/4 inches) with valve shall be provided at low point toward the water outlet.

Water Detection on dry gas circuit

To detect any water leakage (e.g tube leakage) into the gas circuit, a liquid water detector (UT type) may be installed at the place where water could build up.

The level detector shall be installed on the low point (on the cooler or on the related piping) where water could build up.

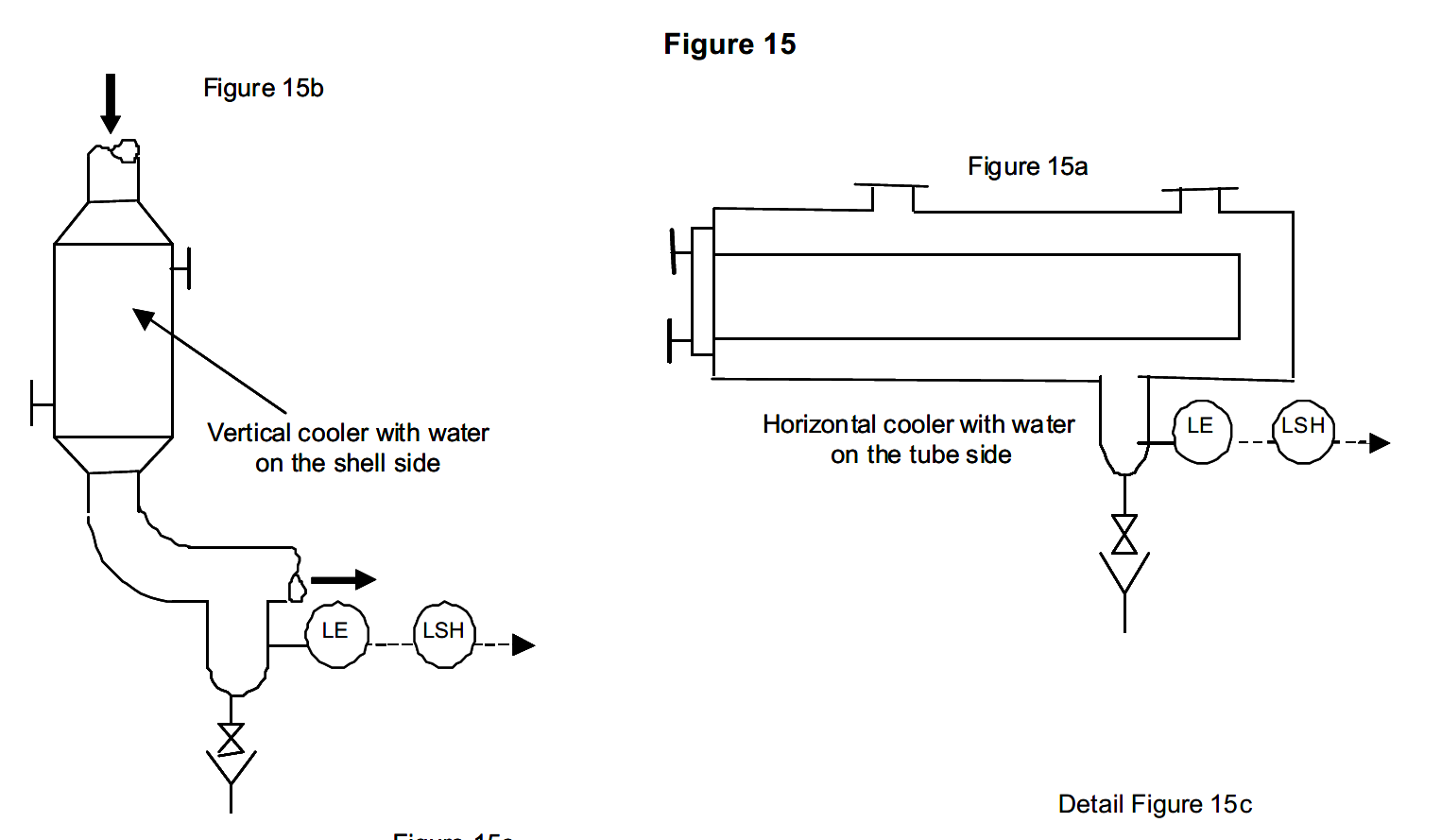

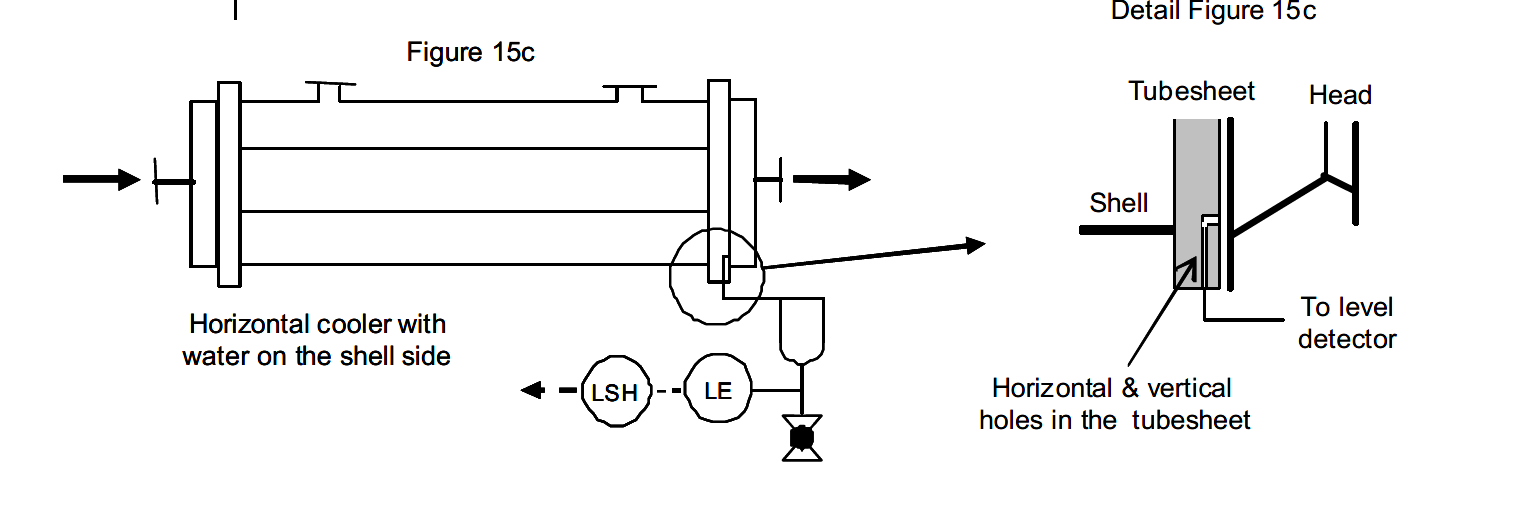

When dry gas flows on the tube side, the detection system shall be installed downstream the cooler (see Fig 15b for vertical coolers and Fig 15c for horizontal coolers)

Note: For dangerous gas, the drainpipe must be collected to protect the operator.

The detection system is required for each dry gas cooler. This water level detection is the recommended solution but alternate solution may be considered. Refer to .... if it is diffucult to install level detector on standard machine coolers.

Example: When the water is on the shell side, a way to achieve the requested detection is to create the drain at the low point in the tube-sheet (see detail of fig 15c). This is done by drilling a horizontal blind hole (12.7mm or 19mm) in the tube sheet from the gas box side and the drilling a vertical blind hole intersecting the horizontal one to be used for drainage purpose and to install the water detector.

아무튼 위의 Fig 15a처럼 구성해서 piping에 Level swtich를 설치할 예정

It is a point level sensor with tuning fork for point level detection.

'Design > Auxiliary Parts inc. Cooler' 카테고리의 다른 글

| TCV (Temperature Control Valve) (0) | 2022.06.29 |

|---|---|

| PP (Personal Protection) (0) | 2022.03.23 |

| [Condensate Drain] 작동 원리 (0) | 2020.10.09 |

| Portable Oil Purifier (0) | 2020.08.12 |

| Check Valve (0) | 2020.08.12 |